The construction industry has evolved with computer-aided design and engineering, paving the way for state-of-the-art construction formwork systems. Architects and engineers use digital tools to design large structures, significantly boosting efficiency, safety, and cost-effectiveness. Along with robust, more durable building materials, these modern formwork technologies have transformed how we construct safe and practical buildings. When you need scaffolding equipment, parts and accessories, visit the established scaffold company near you.

I. What Is Formwork in Construction?

Formwork in construction is essentially the mould or temporary framework into which concrete is poured and allowed to harden, defining the final shape of the structure. This indispensable element has been a cornerstone in building practices worldwide for centuries, with its usage spanning from simple traditional setups to advanced systems seen in projects nowadays. In countries like Australia, various types of formwork have been in practice for over 300 years, supporting the evolution of construction practices.

II. Types of Formwork

Different projects require different solutions, and accordingly, several types of formwork are employed to suit specific construction needs:

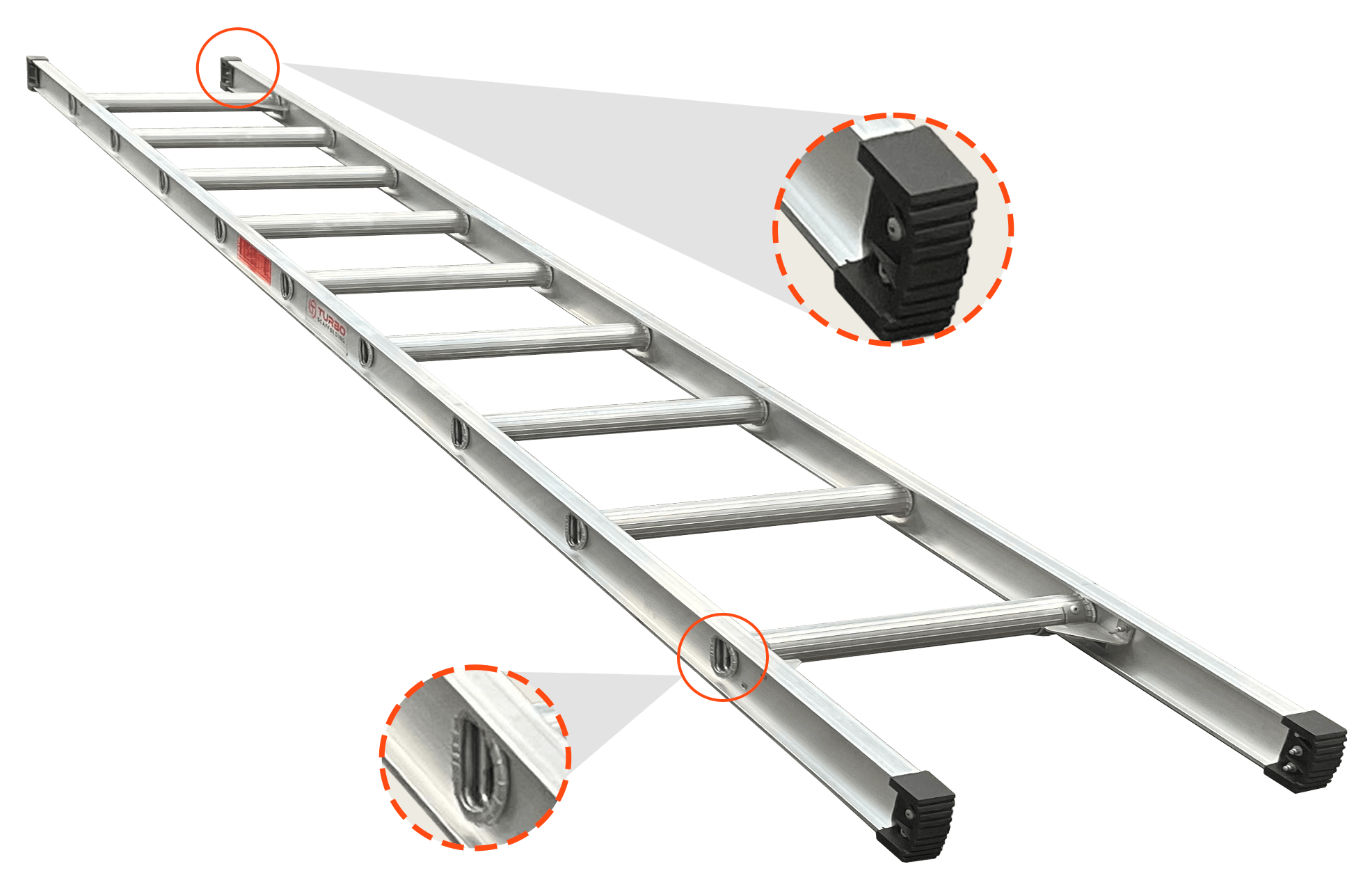

Engineered Formwork: Modern engineered formwork employs preassembled modules framed in steel or aluminium. This approach is efficient, easy to assemble and highly reusable, making it a favourite for construction companies aiming for cost-effectiveness and swift project turnover.

Timber Formwork: As one of the traditional methods, timber formwork uses readily available lumber or plywood. While it offers the flexibility needed for intricate designs and is cost-effective where labour is inexpensive, its durability is limited compared to engineered solutions—especially in large-scale constructions.

Insulated Concrete Formwork: Gaining popularity for its sustainability credentials, insulated concrete formwork is assembled on-site and remains in place after the concrete sets. It offers a low ecological footprint, enhanced thermal and acoustic insulation, fire resistance, and quick installation. This construction formwork is increasingly incorporated into building codes worldwide, making it a strong contender for residential and commercial projects.

III. Sustainability Practices

For eco-conscious construction, sustainable formwork solutions are more critical than ever. Emphasising eco-friendly materials and reusable formwork systems reduces waste and significantly lowers the environmental impact of construction projects.

- ◉Reusable Formwork Components: One core advantage of modern formwork technologies is the knack for reusing components multiple times. Systems made from durable materials like steel or aluminium can be employed across several projects, drastically minimising material consumption and disposal waste. This reusability translates into long-term cost savings and a smaller carbon footprint, which aligns with the growing demand for sustainable formwork solutions.

- ◉Eco-Friendly Material Integration: Eco-friendly materials are vital in these sustainability practices. For instance, recycled steel, reclaimed timber, and innovative composite materials are integrated increasingly into construction formwork. These materials often require less energy to generate and have a lower environmental impact than traditional alternatives. By incorporating these green materials, construction projects contribute to a circular economy, reducing reliance on virgin resources and repurposing waste that might otherwise end up in landfills.

- ◉Energy-Efficient Design and Installation: Advancements in modern formwork technologies have led to designs that optimise energy usage during manufacturing and on-site installation. Lightweight yet robust formwork systems are easier to transport and assemble, reducing fuel consumption and lowering the overall environmental footprint of a project.

- ◉Waste Reduction and Resource Management: Sustainable formwork practices extend beyond the materials used. They also encompass efficient resource management and waste reduction throughout the construction process. Many formwork systems are designed for easy disassembly and reconfiguration, allowing them to adapt to different project needs while minimising on-site waste.

- ◉Compliance with Green Building Certifications: These sustainable formwork practices often meet or exceed environmental regulations and support green building certifications, proving that eco-friendly solutions can go hand in hand with high performance and durability.

The industry is building stronger, more efficient structures and developing a more responsible and environmentally friendly future by integrating these sustainable practices into construction formwork.

The Significance of Formwork in the Construction Industry

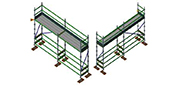

- Matchless Efficiency: Construction formwork is irreplaceable; it enables the rapid and economical creation of concrete structures, significantly reducing project timelines.

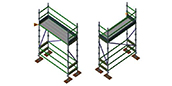

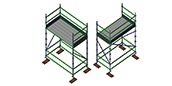

- Enhanced Worker Safety: Formwork provides secure access and working platforms during construction, ensuring safety standards are maintained on-site.

- Cost and Time Savings: By streamlining the floor-to-floor construction process, formwork substantially reduces the project duration and overall costs, allowing more projects to stay within budget.

- Optimised Resource Management: Accurate formwork mobilisation and demobilisation enhance project efficiency and resource utilisation.

- Superior Finishing: The quality of the formwork directly influences the surface finish of concrete structures, ensuring aesthetically pleasing and durable results.

- Structural Integrity: Formwork systems can withstand significant loads, contributing to the overall worker’s safety and stability of the final structure.

The Bottom Line

Selecting appropriate types of formwork is pivotal to the success of any construction project. Whether opting for engineered, timber, or insulated concrete systems, each option presents unique advantages customised to specific project demands. With the rise of modern formwork technologies and a growing emphasis on sustainable formwork solutions, construction projects are efficient, cost-effective and environmentally responsible.