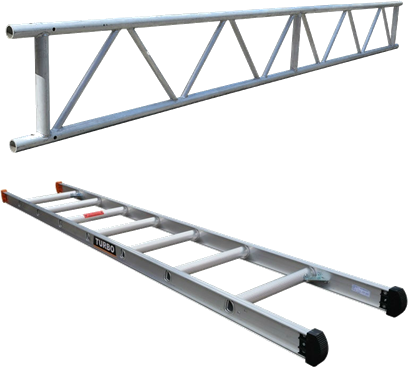

Since decades, ladders are being used as resourceful climbing support though they have their drawbacks. They are prone to stability issues and inconsistent in the middle as it causes bowing problems. Their single span form constitutes an unsustainable solution when measured against today’s work patterns.

In a nutshell, in order to work at heights above the ground level, workers should get access to a secure and comfortable climbing aid, for instance, one that is covered by the tried and tested ladder design – this is the precise reason ladder access tower scaffold erection is so preferred on work sites around the world.

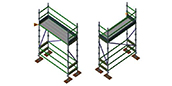

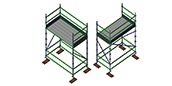

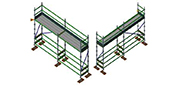

Structure of a Usual Scaffold Frame

The temporary work site frames known as scaffolds can be looked at in varied ways. To enable workers to work at great heights, these are raised work platforms, which securely hold workers and work materials facilitating them to work comfortably. These temporary towers erected are made of metal cross members and special fasteners, fixing tightly parts that lock each piece of the frame in place. Optionally, a ladder access tower-scaffold frame is understood by many as an improved laddering design, though the ladders are kept in-between with platforms and several levels. Keeping this perspective, scaffolding is, in fact, a chain of ladders covered in a strict frame of supporting tubular posts, metal braces, which are allotted horizontal and vertical duties.

Assembled for Secure Scaling

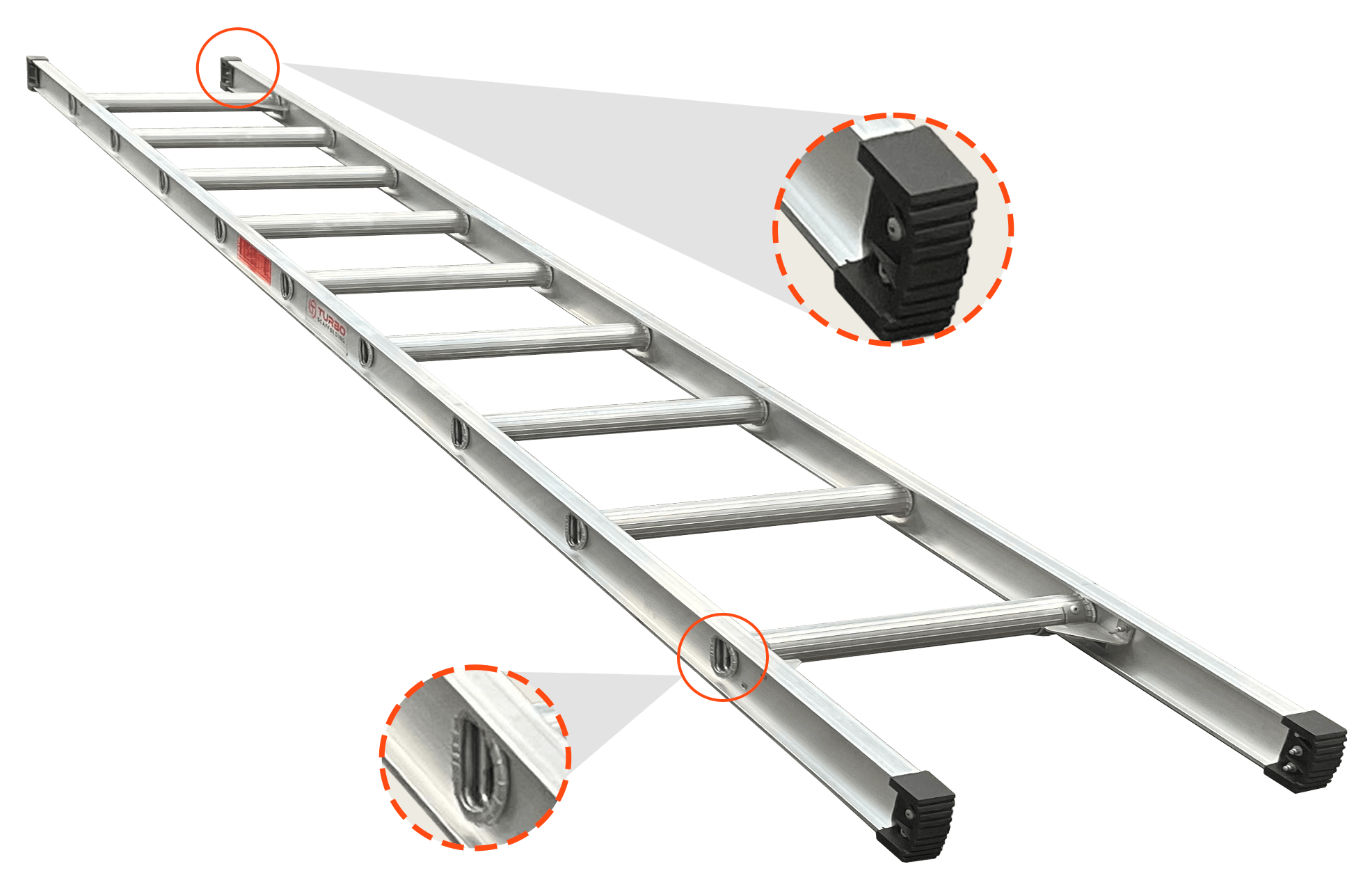

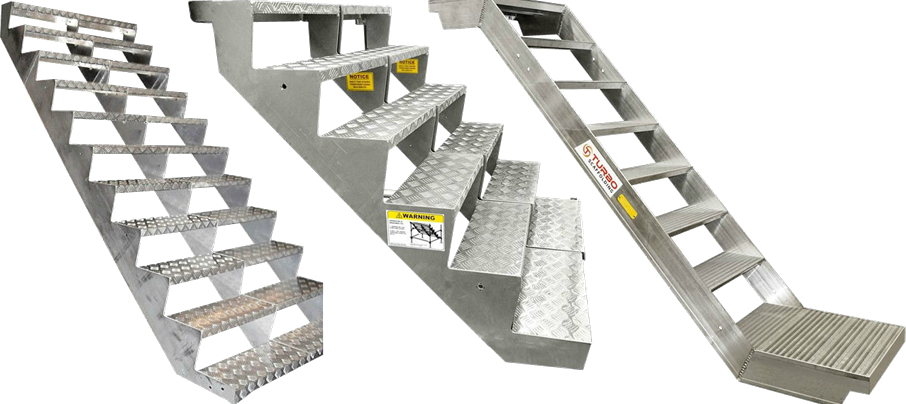

Ladder placement is mostly seen as a complicated part in the erection process no matter how we interpret the structure. The top and bottom of each ladder ought to be angled to guarantee handy upward movement that leaves little flexibility when adjusting the bottom and the top of each skeletal climbing frame. That means the ladders ought to gratify natural human scaling practices while stiffly bonding to the access portals on each platform. When noticed from the ground, the mounting frame of the scaffolding then seems to form a firm grid but a series of slim wedges forms on each row, which is because of the ladders showing off an apparent means of managing the gap between each level.

Securely supported by handrails and other standard safety aids, the standard angle formed by a ladder within the ladder access tower scaffold setup is around 70°, and this angle should never exceed the 80° mark. Moreover, as tower scaffold erections rise so high, each ladder must be checked for faults as this is a vital link in the climbing chain, particularly if the worker is handling the rungs of the ladder and getting stuck because of a tool belt.

Whether you need scaffolding ladders or aluminium stairs or any other scaffold fittings and accessories, you can get them all at one place – Turbo Scaffolding.