Scaffolding is crucial in naval maintenance and construction, providing safe access to ship hulls, platforms and support structures. Aluminium scaffolding systems combine high strength with low weight, making them ideal for defence applications where mobility and durability are essential. Turbo Scaffolding supplies a comprehensive range of aluminium scaffolds engineered to withstand harsh marine environments, ensuring that Australia’s Navy projects proceed smoothly and safely.

Robust and Sturdy Aluminium Scaffolding Systems

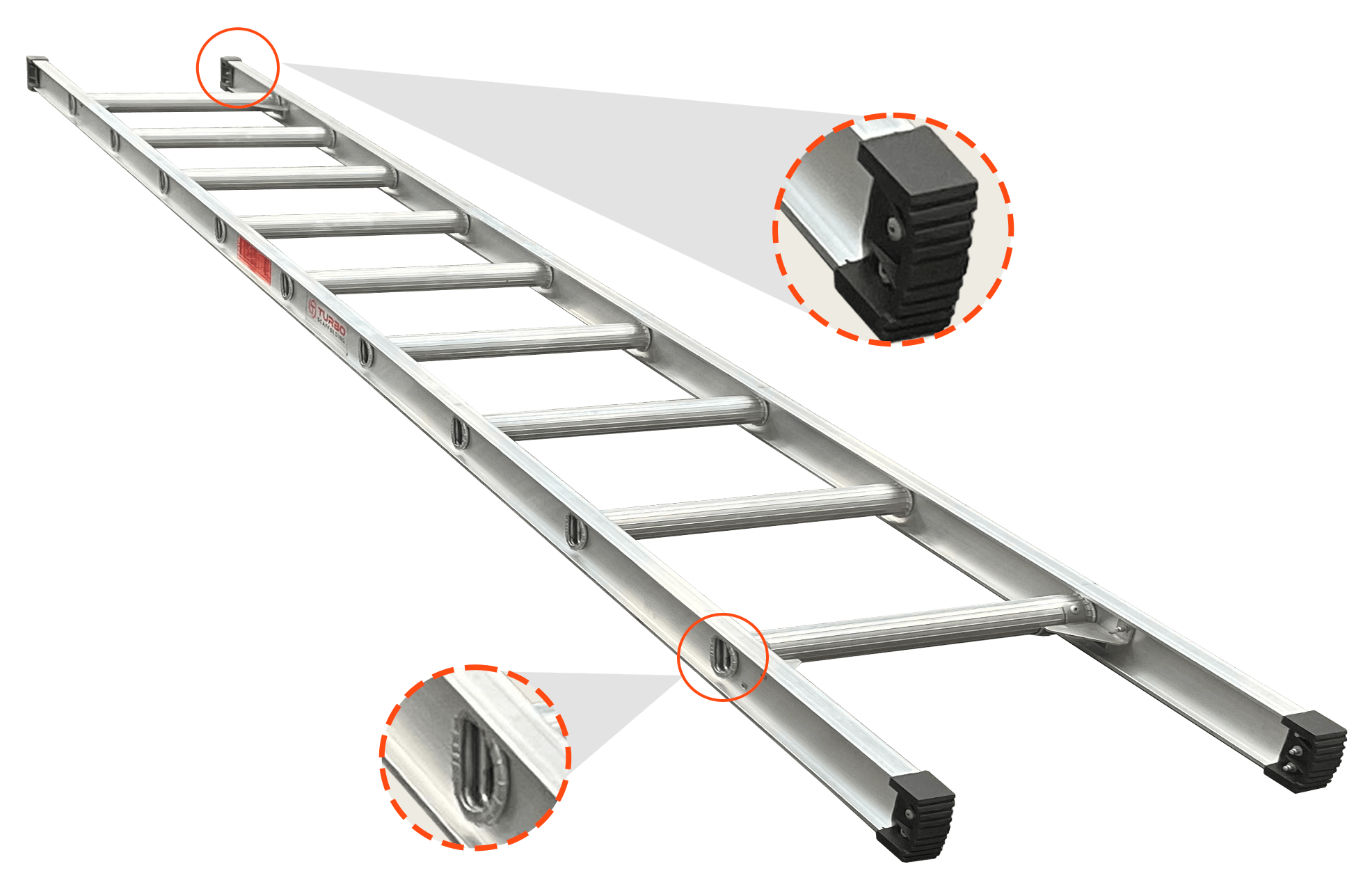

Aluminium offers an excellent strength-to-weight ratio, which means scaffolds resist bending or warping under heavy loads while remaining easily transported. Corrosion resistance is built into every component, from lightweight frames to high-grade fittings, reducing the need for frequent replacements. Turbo Scaffolding’s systems undergo rigorous testing to meet strict Australian Defence Force standards, guaranteeing that platforms remain stable during maintenance, repairs and new construction tasks.

Adaptable Aluminium Scaffolding Solutions

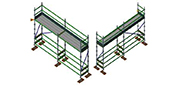

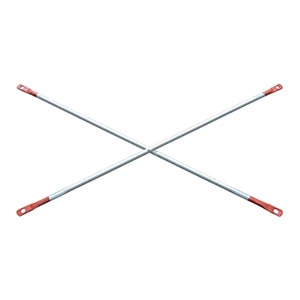

Turbo Scaffolding’s aluminium scaffolding solutions are engineered for quick assembly and dismantling, with modular sections that fit confined spaces on naval vessels or oil rigs. Special anchoring kits secure structures to uneven surfaces, and non-slip decking ensures team safety in wet or windy conditions. These solutions help minimise downtime while meeting maritime safety regulations.

Reliable Marine Scaffolding Solutions

Marine scaffolding solutions must resist salt spray, humidity and constant temperature fluctuations. Turbo Scaffolding applies premium anodised finishes to all aluminium components, preventing corrosion without adding significant weight. All platforms and guardrails comply with Australian standards for fall protection, and mesh panels prevent tools or debris from dropping into sensitive areas. This level of protection supports uninterrupted shipyard schedules and safeguards personnel.

Efficient Aluminium Mobile Scaffold Designs

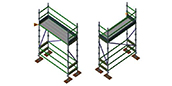

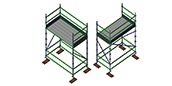

An aluminium mobile scaffold is indispensable for tasks that require frequent repositioning, such as hull inspections or onboard electrical work. Turbo Scaffolding’s mobile units feature lockable swivel castors, easy-adjust platforms, and secure base frames.

Teams can move scaffolds between workstations with minimal effort, saving labour hours and reducing manual handling risks. Platforms extend to various heights, accommodating low-level access around machinery and higher tasks like mast rigging inspections.

A Leading Industrial Scaffolding Supplier

As a trusted industrial scaffolding supplier, Turbo Scaffolding manages every stage of a navy project, from planning to delivery. Dedicated project coordinators work alongside naval engineers to select the correct system configurations, confirm load capacities and schedule logistics. On-site technicians deliver, assemble and certify each scaffold, providing digital inspection reports to ensure compliance. This integrated service model keeps materials flowing, avoids project delays and demonstrates Turbo Scaffolding’s commitment to Australia’s defence needs.

Wrapping Up

Australia’s Navy relies on scaffolding that combines toughness with adaptability. Turbo Scaffolding’s durable aluminium scaffolding systems deliver on both fronts, offering robust platforms, specialist scaffolds and agile mobile units. As an experienced industrial scaffolding supplier, Turbo Scaffolding meets stringent marine and defence standards, helping naval teams complete essential maintenance and construction safely and efficiently.