Small but mighty, Acrow props have transformed the construction industry by offering an efficient solution for temporary structural support. This blog explores the fundamentals of Acrow props, their functionality, benefits, and the critical aspects of their use in building repairs and construction projects.

What Is an Acrow Prop?

Acrow props, also known as shore props, acrow jacks, or post shores, are adjustable vertical supports used for temporary load-bearing in construction and building repairs. Acrow props designed to provide stability during projects, such as beam replacements or alterations to door and window frames, have become indispensable for construction sites worldwide.

Acrow props originated in 1935 when Swiss inventor William de Vigier introduced them as a more flexible and cost-effective alternative to wooden props. Their durability and versatility have since made them a preferred choice for contractors and builders.

How Does an Acrow Prop Work?

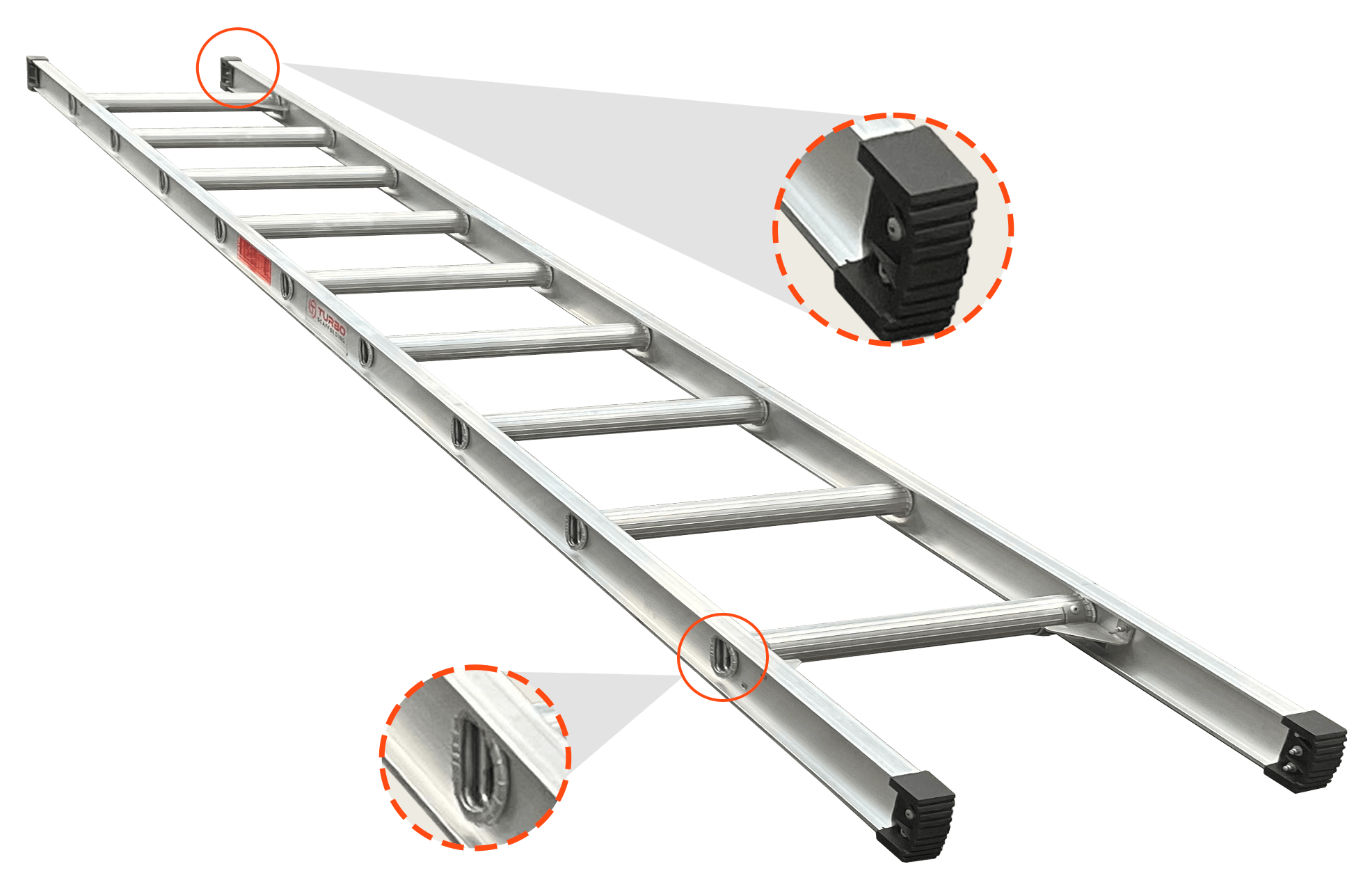

An acrow prop consists of two telescopic steel tubes, an outer tube with a welded base plate and an inner tube with a welded top plate. Key components of an acrow prop include:

- Telescopic Tubes: These adjustable tubes allow length customisation to suit specific requirements.

- Pin Mechanism: A pin locks the tubes into place after coarse adjustments.

- External Thread: Achieve fine-tuning adjustments using a threaded mechanism.

Alternative acrow prop designs feature threaded pipes that screw into each other. And ratcheting or clamping systems can be used for adjustment instead of pin mechanism.

Benefits of Using Acrow Props:

Acrow props have become a staple in construction due to their numerous advantages:

- Versatility: Acrow props are suited for various tasks, including supporting scaffolding, falsework, or masonry during building repairs.

- Simplicity: A straightforward three-step setup makes acrow prop installation quick and easy, often requiring just one person.

- Flexibility: Their lightweight design (around 13kg) and dual adjustment system make them easy to move, position, and reconfigure as needed.

Acrow Props Standard Sizes and Weight Capacities

Acrow props are available in five different sizes, ranging from size ‘0’ to size ‘4’ offering flexibility for diverse projects:

- Size 0: Extends from approximately 1,050mm to 1,800mm.

- Size 4: Extends up to 4,900mm.

These props can support axial compression loads ranging from 7kN to 42.5kN, with a maximum load capacity of approximately 4,300kg.

Common Uses of Acrow Props in Construction

Acrow props serve multiple purposes, including:

- Shoring Support: Temporarily supporting beams, ceilings, or walls during structural repairs.

- Scaffolding Brace: Stabilising scaffolding systems in construction sites.

- Falsework: Holding up structures or frameworks during construction.

Their adaptability makes them the preferred solution for large construction projects, as well as, small-scale repairs.

Safe Use of Acrow Props in Construction

Ensuring the safe use of acrow props in construction involves careful planning and adherence to safety guidelines. Factors to consider include:

- Load Requirements: Determine the weight and size of the load that needs support.

- Prop Placement: Ensure proper positioning and alignment to distribute the load evenly.

- Support Mechanisms: Use additional tools such as strong boy wall supports, timber needles, or masonry supports when necessary.

- Extension Limits: The safe working load decreases as the prop’s extension increases.

Acrow Props for Sale: Choosing the Right Option

When selecting acrow props for sale, assess your project needs, including size, weight capacity, and additional support requirements. Reputable suppliers can offer expert advice and ensure you find the right props to complete your project safely and efficiently.

Wrapping It Up

Acrow props have become a fundamental tool in modern construction, offering reliable temporary support for diverse projects. Their versatility, ease of use, and load-bearing capacity make them invaluable for shoring, scaffolding, and building repairs. By following proper installation guidelines and consulting professionals, you can maximise their potential while ensuring safety on-site.

Structural engineers can guide you in prop selection and designing secure support systems for complex projects. For all your propping and structural support needs, get professional guidance from the expert team at Turbo Scaffolding for the best solutions for your construction requirements.