Scaffolding Inspection and Maintenance Guide: What Every Site Manager Must Know

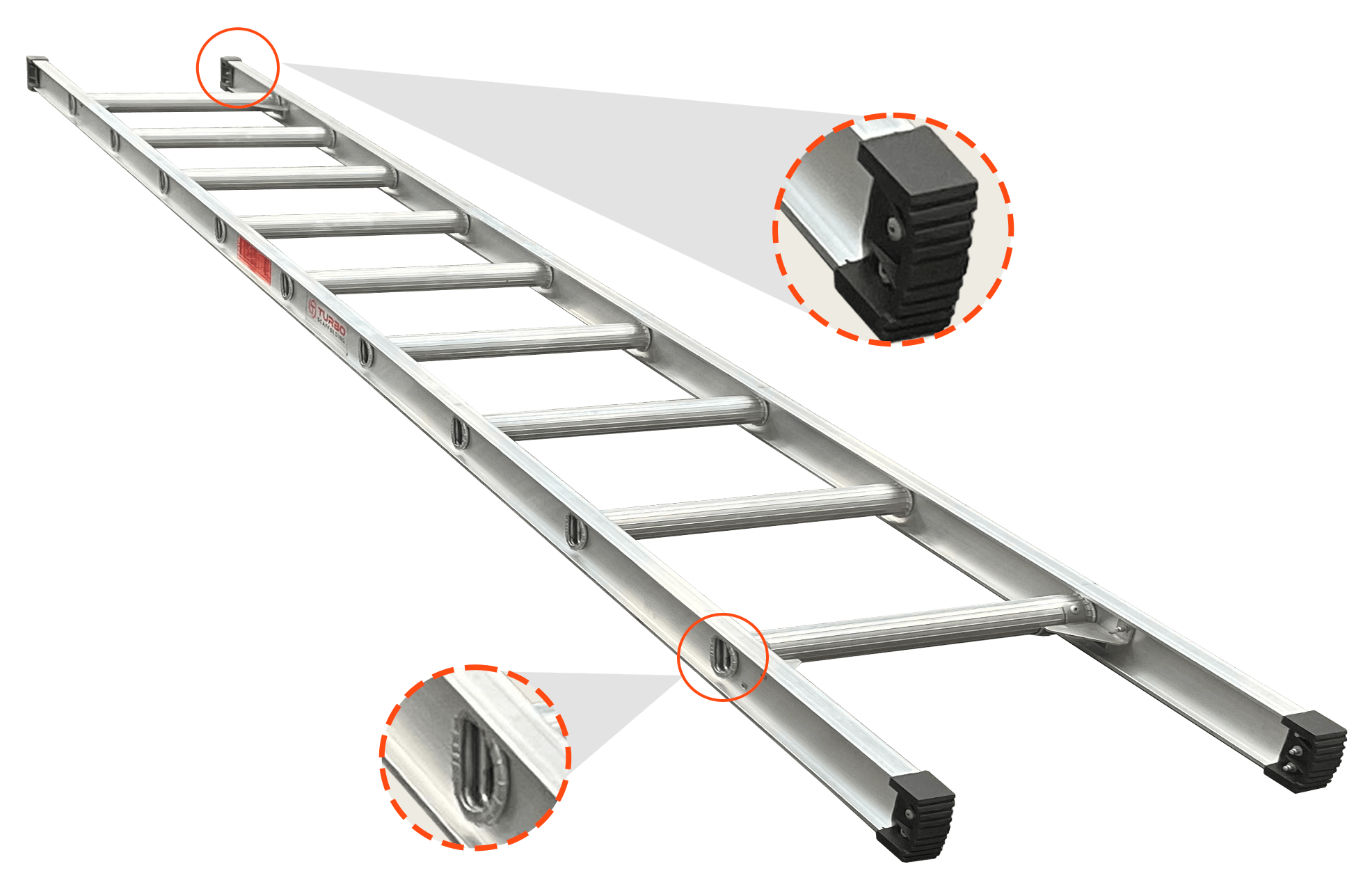

Keeping a site safe depends on many moving parts, and scaffolding sits right at the top of that list. A solid frame gives your crew the confidence to move, lift, build and complete tasks without second-guessing the ground beneath them. But even the strongest setup can turn risky if…

View More