Well, the high-quality commercial scaffolding that is robust and durable can withstand a hit. Suppose, the frame pushes a harsh concrete wall or a tool drops, the light metal tubing will ignore the impact effortlessly. However, what’s in store when the temporary erection gets extremely impaired.

Here Are Some Major Causes That Can Wreck Damage To Scaffolds:

-

General Deterioration

Scaffolding systems fit commercial and industrial work sites with multi-level work platforms at height. Accordingly, the gear undergoes harsh impacts all through the passage of a regular day’s labour. The stacked up pieces stroke against each other when you transport the equipment. To reduce this effect, use appropriate work-piece piling practice.

-

Poor Methods of Scaffold Erection

It’s recommended to adhere to WHS Regulation (The Work Health & Safety Regulation) and other scaffolding safety tips at all times. In fact, the framework shouldn’t gain uneven pressure. An appropriately oriented scaffolding component will pair with one or more of its neighbours to withdraw the loading effect of every downward directed measure of kinetic energy. To shield scaffolding from damages, fittingly built-in fasteners, stabilizing mechanisms, tower-to-structure support lines are used.

-

Overloading Problems

The load-supporting frames are made by competent scaffolding erection professionals. The scaffolding holds workers, building materials and its own weight, right up to the topmost platform. Nonetheless, the scaffolding structure will attract damage if that load goes beyond a set limit. Therefore, workers should take sufficient care, not to overload platforms.

-

Inappropriate Work Protocols

If there is a team member on the top platform who isn’t thorough with WHS Regulation, he may leave his scaffold tools and construction materials in utter chaos. To resolve this problem, the employee requires a course revision that will cure his unruly habits.

-

The Unfolding of Natural Events

It is quite common that intense weather conditions can harm scaffolding towers. Imagine for a moment that we’re talking about a less-than-stellar system, one that greatly requires maintenance. A hot tropical day’s heat is affecting the uncovered tubing. The colder evening starts as soon as the sun goes down. Then after rainfall occurs, which pours down in sheets. Although these are different environmental conditions, they do occur. When different weather conditions such as cold, heat and rain combine, they can cause oxidization/ rust formation.

Summing Up

All these problems can wreak damage to scaffolding structure and equipment, and it’s difficult to pinpoint any one major cause. Certainly, nobody has any control over the atmospheric conditions apart from scheduling an efficient maintenance program. Therefore, to safeguard against the above-listed major problems, the vital measures include:

- Scheduled maintenance program

- Presence of knowledgeable, skilled and experienced personnel &

- The right training for all workers

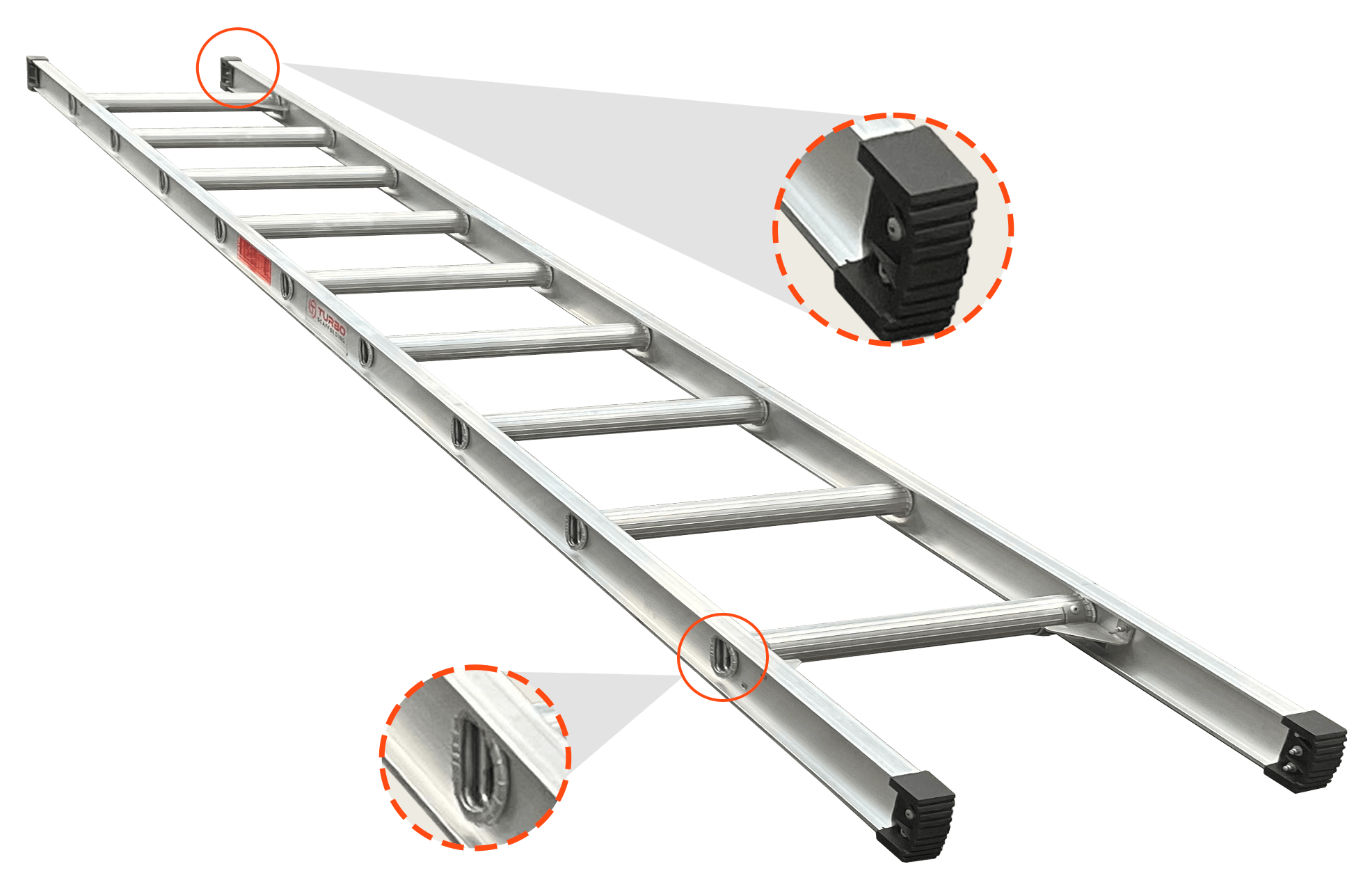

Construction contractors and builders can buy high-quality scaffolding equipment from standard scaffolding suppliers like Turbo Scaffolding at attractive prices.